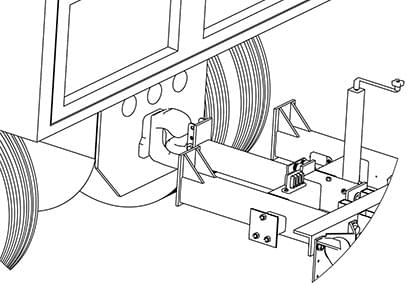

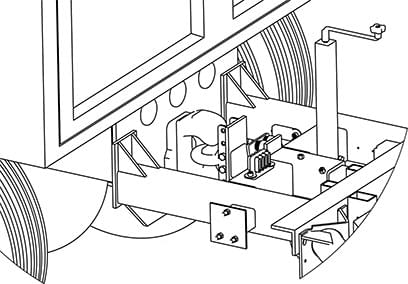

The Scorpion Towable Attenuator requires little or no modification to host vehicle or additional mounting hardware beyond the standard pintle hook and ½" thick × 32" wide steel frame plate. This single point attachment makes the installation of the Scorpion TA quick and easy.

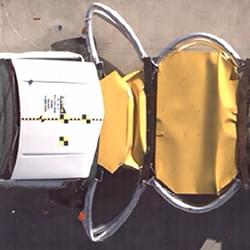

The Scorpion's proven modular design crushes in progressive states allowing quick and economical replacement of damaged parts. Rear axle placement improves attenuator stability and prevents the tail from "bottoming out" on driveways or uneven surfaces. The overall length of the Scorpion TA is only 17' 10", the shortest on the market, and is available in shorter (13') lower speed TL-2 (45 mph) model, which is ideal for congested city streets or where posted speeds are 45 mph or less. The integrated electric brake system comes standard on all Scorpion Towable Attenuators and are automatically activated in the event of separation or hitch failure. Optional Arrow or Message Boards can easily be attached to the Scorpion Towable Attenuator.

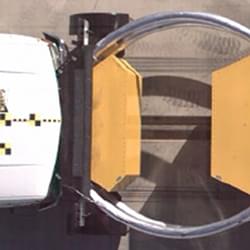

The Scorpion Towable Attenuator gives full width protection to the back of the host vehicle and protects the "coffin corners" of the truck. The Scorpion TA is NCHRP 350 tested and approved for all mandatory and optional offset and angled impacts.